Stage two – Process Qualification: All through this stage, the process style is confirmed as staying effective at reproducible industrial manufacturing.

Concurrent validation is a pragmatic approach that balances the need for rapid solution availability While using the necessity for arduous excellent assurance. By making sure thorough checking, sturdy documentation, and demanding adherence to predefined standards, it serves to be a worthwhile Device in maintaining products integrity beneath time-sensitive conditions.

Like First validation, revalidation calls for thorough documentation to demonstrate compliance and safeguard product or service integrity. It really is essential for preserving process dependability and Assembly evolving regulatory and operational standards.

Inflexibility: Retrospective validation doesn't allow for serious-time process optimization. It focuses only on past performance, probably overlooking existing inefficiencies or areas for advancement.

This chance-primarily based approach not just improves the effectiveness of validation actions but in addition reinforces the adaptability of processes while in the face of adjusting circumstances. All characteristics and parameters are evaluated regarding their roles from the process and their effect on the ultimate solution or intermediate supplies and reevaluated as new information gets to be readily available.

Goal: This process includes re-evaluating and re-creating proof that a technique proceeds to operate inside of the required parameters.

Possibility assessment plays a crucial part in process validation. By figuring out potential risks and areas of issue, providers can aim their validation attempts on significant process validation examples process parameters and measures.

Process validation is a crucial part of high-quality assurance from the manufacturing industry. It entails the gathering and analysis of information in order that a process continuously produces items that meet predetermined technical specs and high-quality necessities.

PQ is the ultimate move read more inside the process qualification stage and includes verifying the process continually makes solutions conforming for their predetermined specifications.

Process validation involves a number of actions occurring more than the lifecycle with the solution and process.

The diploma of essential Manage around These attributes or parameters is proportional to their danger to your process and process output.

Such predicaments require watchful preparing, in depth justification, and approval by licensed personnel. This makes certain that even underneath the pressure of rapid generation, merchandise basic safety and high-quality usually are not compromised.

A few consecutive batches shall be selected for process qualification getting same / identified established of kit

Techniques need to run for 20 consecutive Doing work days, and deviations into the treatment needs to be recorded. The acceptance criteria really should be compared towards the general performance check results to formulate conclusions over the validity of the tools/system.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Shannon Elizabeth Then & Now!

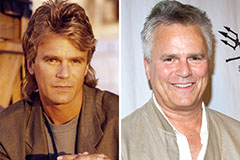

Shannon Elizabeth Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!